Strainers

Tee Strainers

Tee Strainer is designed to remove solids form Pipe Line where a COmpact accessible strainer is needed for protection of pumps, Valves, and other similar equipment.Tee Strainer is fabricated from pipes and plates or standard equal Tee and Flange Strainer elements are made of M.O.C. -Body - MS / CSStrainer Elements - SS / Bronze Steel perforated sheet or wire mesh supported by perforated Tee Type Strainer many times a structural skeleton. Made of flats and round bar is used to support wire mesh.

Features:

Compact Size and Low weight.

Covers furnished with blow off tapping.

Low Pressure drop across the filter.

Low Installation and maintenance.

Easy cleaning or replacing the element.

Machined tapered seat to securely receive the screen cover gaskets designed to hightemperature service.

Scrwed : 50 NB - 150 NB

Flanges : 150 NB - 600NB

Basket Type Strainers

Perfectt Basket type Strainers are used to filter foreign matter from Pipe Line by using screen removable from top. The screen is inthe form of abasket with a handle. All the clogged material retained by the screen can be easily removed and made ready for next change over. They are available in varity of materials and finds appilaction in various chemical process industry. They are designed for application where easy maintenance and large capacity straining area are needed.

Features:

Compact Size and Low Weight.

Large dirt holding capacity, Long cleaning cycle time.

Top removal of screen with a lifting handle.

Permits rapid servicing.

Filters are manufactured up to 48" NB Size and Filtration down up to 5.

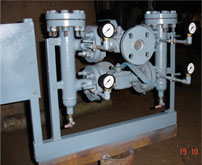

Duplex Strainers

Perfectt Duplex Filters provide ease of cleaning the element without interruption to the process i.e. where the flow cannot be shut down for cleaning the screen by use of butterfly Valves . Duplex Strainers feature a single shaft drive to operate the flow diverter valves BAskets are gasketed and surely posituned to prevent particles by - pass. They are available in fabricated and cost construction.

Features:

Compact Size and Low Weight.

Low Pressure drop across the filter.

Large dirt holding capacity and allows frequent cleaning.

They are very economical as they can be fabricated according to the requirement with choice of valves.

Size: 25 NB - 600 NB

Y Type Strainers

These types of strainers are named after their shape. It helps in the remval of foregin bodies in pipe line and use line trouble free service and freedom costly repairs or replacement for large area straining perforated screen lined with wire mesh can be used. They are used inhigh temperature and pressure lines gas or liquid and even in suction areas.

Material Of Construction:

Y Strainers can be made of Cast Iron,CArbon Steel, SS304, SS316 and as per customers request with flanged connection for large size and socket weld type end connection for samller size non ferrous are with threaded Connections.

Features:

Compact Size and Low Weight.

Covers furnished with blow off tapping.

Low Pressure drop across the filter.

Low Installation and maintenance.

Easy cleaning or replacing the element.

Machined tapered seat to securely receive the screen

cover gaskets designed to high temperature service.

Screwed:15 NB - 50 NB

Flanges:15 NB - 900 NB

Fabricated Strainers

Perfectt Strainers are designed and fabricated for long service in various styles and types to work ubder different conditions of temperature and pressure. They are available in variety of materials & size to fit into existing piping to achive the required clean pressure drop.

Features:

As per customer requirement of size and weight.

Achieve the required pressure drop across the filter.

Adequate strength of elements and housing.

Permits rapid servicing i.e., ease of cleaning or replacing the element.

Low Cost.

Component or parts suitable for and compatible with hydralic fluid concerned

Pressure Sand & Carbon Bed Strainers

Such Filters are designed horizontal or vertical type with back wash facility according to requirement they are manufactured from best quality carbon steel plates. Large vessels are provided with access manhole. Filte media in sand filter consist of a bed of fine quartz sand supported by layers of graded well washed selected gravels. In the carbon filter the filtering bed consist of activated carbon granules of various sizes. Perfectt Multi Bag FIlters are manufactured to handle large flow rate with cost of maintenance.

Features:

Adequate Stength housing.

Backwash Facilty provided.

Acess manhole provided for refilling chanaging filter media.

low cost - Initial as well as service cost.

Depending upon the thickness of the metal, 0.020” thru 1” perforation is available. In the case of metal or stainless steel, the smallest perforation available are usually twice the thickness of the metal. Rather than the use of light gauge sheet metal which would be necessary in obtaining exceptionally small perforations, we suggest heavy gauge perforated metal screens with large perforations lined with wire mesh cloth. This is not necessary for small strainers where lighter gauge metals are satisfactory.

Mesh:

The term “Mesh” applies to woven wire cloth and should not be confused with perforated sheet metal. Mesh screens are satisfactory for small size cast strainers, but are unsuitable for longer strainers except as a liner for perforated metal basket or screen. Mesh screen are primarily furnished for very fine straining with openings so fine they cannot be obtained in Perforated metal. Example: 100 mesh means 100 vertical and 100 horizontal strands of wire to the square inch, resulting in 10,000 openings of 0.0055 sq. inch.

Ratio Or Capacity : The 6 to 1 ratio means that the open area of the screen or Basket should be equal to six times the cross-sectional area of the corresponding pipe size.

Strainer Selection:

Perfectt Engineers have observed that to keep the pressure drop within reasonable limits and to have effective straining it is necessary that the free straining area will be a least three times the pipe cross sectional area in the case of Y - Strainers and six times in the case of Basket type strainers.

Select the anticipated clogging % at the left of the chart. The example shows a basket 75% clogged. Then, follow that until the curve is intersected. From that point follow downward to the scale along the bottom to read the pressure drop multiplying factor, in this case 4. The resulting pressure drop across the basket at 75% clogged is four times as great as that for a clear basket.

Example: How much is the Pressure drop through a 12” Y” strainer for a flow of 1000 GPM of water at ambient temperature with 1/8” perforated basket which is 75% clogged? Find the pressure drop for a clean basket from the curve. At 1000 GPM it is 0.3 psi. As prescribed, the multiplying factor for a 75% clogged basket is 4. The pressure drop is then 03.psi x 4 = 1.2 psi.

Select the anticipated clogging % at the left of the chart. The example shows a basket 75% clogged. Then, follow that until the curve is intersected. From that point follow downward to the scale along the bottom to read the pressure drop multiplying factor, in this case 4. The resulting pressure drop across the basket at 75% clogged is four times as great as that for a clear basket.

Example : How much is the Pressure drop through a 12” Basket strainer for a flow of 2500 GPM of water at ambient temperature with 1/8” perforated basket which is 75% clogged? Find the pressure drop for a clean basket. At 2500 GPM of water the pressure drop is 0.2 psi. As described, the multiplying factor for a 75% clogged basket is 4. The pressure drop is then 02.psi x 4 = 1.8 psi.